Gates/Doors - Forged

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

In order to be placed in this category, all gates and/or doors, excluding driveway gates must contain custom hand forged elements.

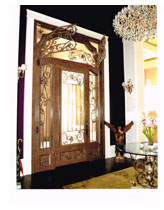

Gold Winner:

Atrium Homes

El Paso, Texas

The design was inspired by the Designer and drawn by the fabricator. The complete project from drawings, finish selection,

The fabrication took 640 hours and the finish took 120 hours.

Silver Winner:

Wiemann Metalcraft

Tulsa, Oklahoma

Wiemann Metalcraft created a forged door and jamb for a residential home.

The door measures 9' by 4'-6'

The most difficult part about this project was the curved jamb and the glass.

Bronze Winner:

Loyal Wrought Iron Co. Ltd.

Guangzhou, China

This door mixes traditional and modern culture and represents the popular trend nowadays.The door consists of six big Chinese Knots, inherits Chinese traditional culture and expresses best wishes. The bronze flowers catch people’s eyes at first sight and is the finishing point of this door. The door is made of Low Carbon Steel and holds bronze flowers, a double-sided lock with handles, 3/4" tempered insulated glasses and removable fly-screen, etc. The door was created with mixed cutting techniques and forging. The scroll works was made by skillful workers and the smooth curved plate was done by exacted machines. The greatest challenge to make this door was the symmetry; symmetry of two door slabs, symmetry of the same door slab. Every small part of one slab is the same as another slab, and you can find the same ones in the same slab as well. So it requests exact radian, correct direction and precise dimension of each scroll works. The Electrophoresis technique was used instead of the galvanizing technique, which is better to prevent the door from rusting. The door has powder coating not spray paint. A faux finish was done with a brush at the end.